Solar power plays a central role in Europe’s move toward a cleaner and more secure energy system. Today, silicon panels dominate the market. However, they are heavy, rigid, and hard to adapt to new uses. Because of this, many emerging applications cannot use them easily.

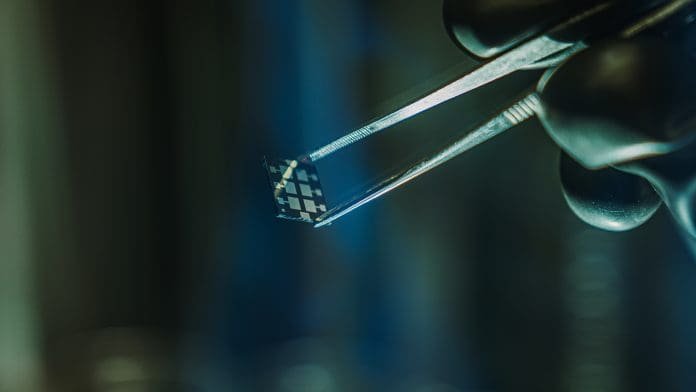

Thin-film solar technologies offer a different path. Among them, perovskite solar cells stand out. They are lightweight, flexible, and can be made at low temperatures. As a result, they open the door to solar power in places where traditional panels do not work well.

Why tin-based perovskites matter

Perovskite solar cells have improved at a remarkable speed. Their efficiency now exceeds 27 percent. Despite this success, most high-performing devices rely on lead. This creates environmental and social concerns that limit large-scale use.

SMARTLINE PV addresses this issue by replacing lead with tin. Tin-based perovskites share many of the same strengths. They absorb light efficiently and move electrical charges well. Importantly, they avoid the toxicity linked to lead.

Researchers have already reached efficiencies above 17 percent with tin perovskites. Even so, major challenges remain. Tin crystallises too quickly, forms many defects, and degrades when tin changes its chemical state. These problems reduce efficiency, stability, and reproducibility.

Controlling crystallisation to improve performance

SMARTLINE PV focuses on better control of how tin perovskite films form. The project designs new crystallisation mediators that slow crystal growth. This leads to smoother films with fewer defects.

At the same time, the team studies safer solvents and stabilising chemical interactions. These choices help keep tin in its desired state and improve long-term stability. Together, these steps move tin perovskites closer to reliable industrial use.

Plasma-assisted processing for scale-up

Traditional perovskite production often uses anti-solvent dripping. This method wastes solvents and does not scale well. It also makes large area manufacturing difficult.

Instead, SMARTLINE PV develops plasma-assisted crystallisation. This approach triggers fast and controlled film formation without anti-solvents. It works at low temperatures and fits well with roll-to-roll production.

Because of this, manufacturers can coat large flexible surfaces in a continuous process. Energy use drops, material waste decreases, and production costs fall. These advantages are critical for future commercial deployment.

Designing devices for stability and flexibility

Material quality alone is not enough. Device design also matters. SMARTLINE PV develops interlayers tailored for tin perovskites. These layers improve charge extraction and reduce losses.

In addition, the project explores new device layouts that bend without damage. This improves mechanical durability and helps devices survive real-world conditions. Through this combined effort, the project targets efficiencies above 20 percent, a level that would make tin perovskites highly competitive.

Coloured solar modules for buildings

Solar panels in cities must do more than generate power. They must also look acceptable. SMARTLINE PV addresses this need through the MorphoColor concept.

Inspired by butterfly wings, MorphoColor uses photonic structures instead of pigments. Patterned surfaces and thin layers create vivid colours through light interference. Importantly, this does not compromise performance.

As a result, solar modules can match architectural designs. Facades, roofs, and sunshades can produce electricity while enhancing a building’s appearance. This is especially valuable in dense or historic areas.

Sustainability and circular design

Sustainability guides every stage of SMARTLINE PV. Low-temperature processing reduces energy demand during manufacturing. Removing lead improves environmental safety and public acceptance.

The project also considers recycling and end-of-life options from the start. By applying circular design principles, it reduces waste and lowers the overall carbon footprint of the technology.

Demonstrators that prove real-world value

To move beyond the lab, SMARTLINE PV builds practical demonstrators. Flexible tin perovskite modules power small IoT devices. These systems can operate without batteries or maintenance.

In parallel, building integrated demonstrators show how coloured modules work in roofs and sunshades. Outdoor testing provides data on performance, durability, and user response. This feedback supports future market adoption.

A step toward next-generation photovoltaics

SMARTLINE PV shows that tin-based perovskite solar cells can move from research to real applications. By combining materials science, scalable processing, and thoughtful design, the project addresses key barriers at once.

As a result, it supports wider use of solar energy in everyday settings. It also contributes to a cleaner and more flexible built environment across Europe.