The BBC stated that Swedish start-up Modvion has successfully constructed the world’s tallest wooden wind turbine, reaching an amazing height of 150 meters, in a landmark step towards eco-friendly wind power.

This ground-breaking project promises a bright future for sustainable energy solutions while challenging the dominance of steel in turbine manufacturing.

Modvion’s Chief Executive, Otto Lundman, expresses enthusiasm about the project’s potential, emphasising the advantages of utilising wood for wind power. The turbine, located just outside Gothenburg, has recently commenced operations, supplying electricity to the Swedish grid and powering approximately 400 homes with its 2-megawatt generator.

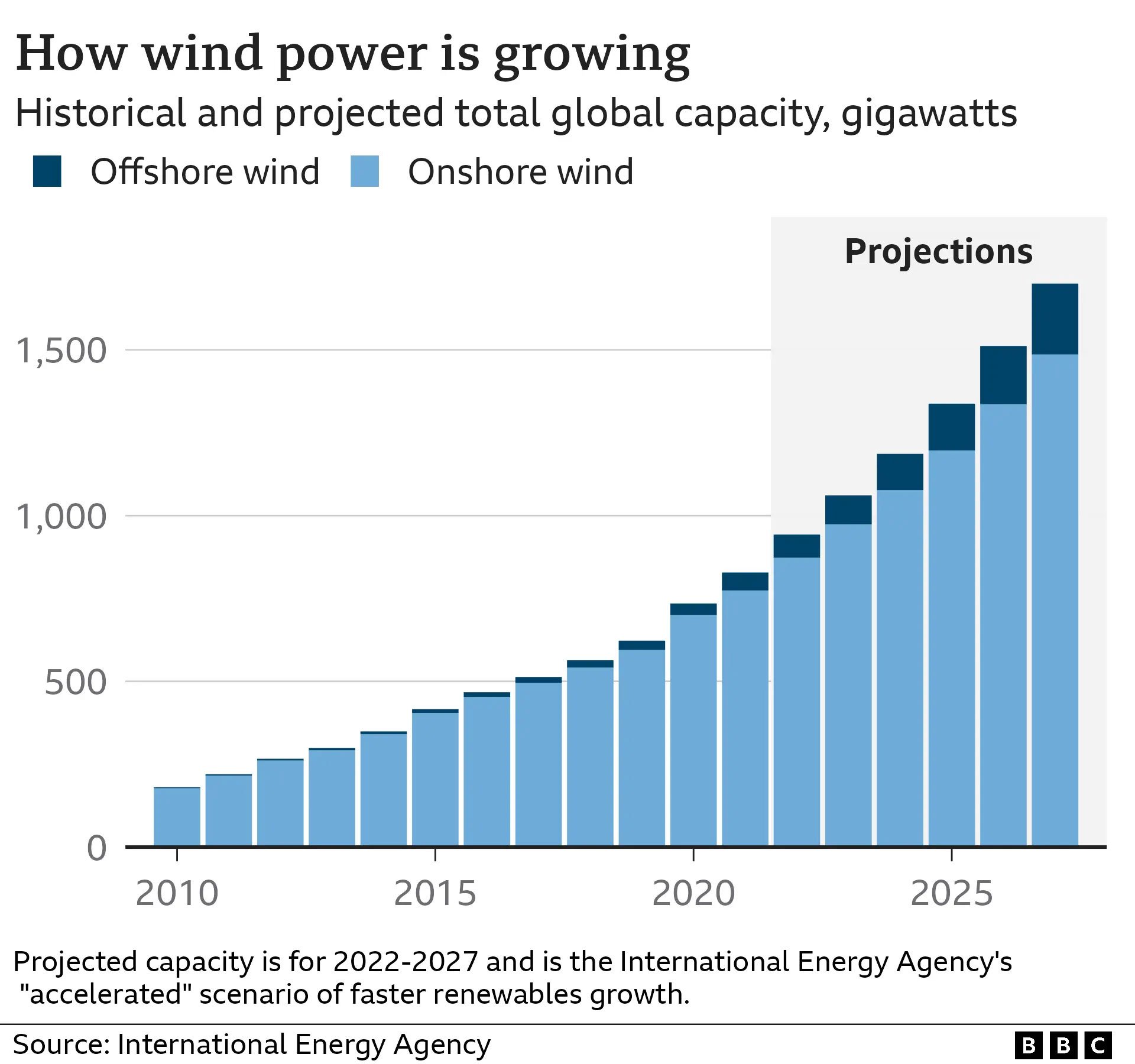

Unlike traditional steel turbines, which dominate the industry, Modvion’s wooden turbine presents a compelling alternative. Lundman envisions pushing the boundaries of wood and wind to even greater heights, addressing the limitations posed by steel, particularly in onshore projects.

Steel, while robust, faces challenges in transportation, especially as the demand for taller turbines with larger generators grows. The cylindrical steel towers required for support have to increase in diameter, creating logistical challenges in delivering these massive structures to turbine sites.

Upon close inspection, the Modvion wooden turbine shares external similarities with its steel counterparts. Both feature a protective coating and blades made primarily from fibreglass attached to a generator. However, the distinctive difference becomes apparent inside the tower, where the walls showcase a unique curved raw wood finish reminiscent of a sauna.

The strength of the 105-meter tower lies in the 144 layers of laminated veneer lumber (LVL), with varying grain in each 3mm-thick layer of spruce. This innovative use of wood and glue allows for a lighter construction compared to steel, enabling the building of taller turbines with reduced material.

Lundman and Modvion co-founder David Olivegren highlight the key selling point of their wooden turbine – the ability to construct towers in smaller, easily transportable modules. This modular approach aims to simplify the construction of tall towers and facilitate transportation to challenging locations.

While some experts, such as Dr Maximilian Schnippering from Siemens Gamesa, point out potential challenges in increased transportation and installation efforts, Vestas, a major investor in Modvion, sees “tremendous potential” in taller turbines, with wooden structures playing a significant role.

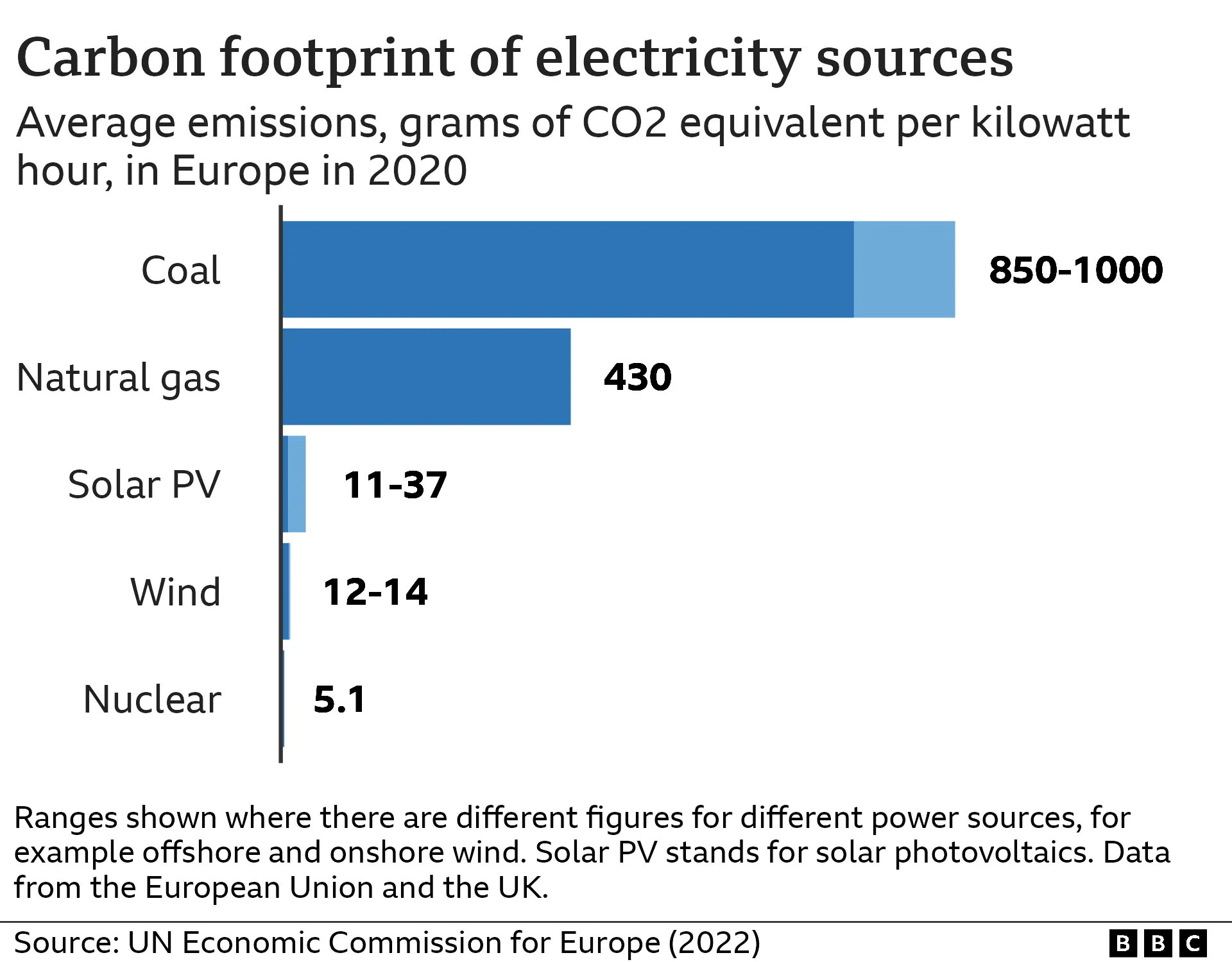

Modvion’s wooden turbine not only offers a sustainable solution but also boasts a negative carbon footprint compared to its steel counterparts. The use of wood sequesters carbon dioxide from the atmosphere, making the turbines environmentally friendly. Approximately 200 sustainably farmed spruce trees contributed to Modvion’s tower, showcasing a commitment to responsible forestry practices.

Renewable energy giant Vestas acknowledges the economic viability and sustainability of Modvion’s wooden turbine, heralding a potential shift in the industry. As the world’s largest turbine manufacturers focus on reducing the carbon footprint of steel, Modvion’s innovation introduces a compelling alternative, bringing the industry one step closer to a sustainable energy revolution.

Looking ahead, Modvion anticipates building even taller turbines and aims to establish a facility producing 100 wooden modular turbines annually by 2027. With a vision for 10% of global turbines to be wooden within a decade, Modvion’s ambitious endeavours align with the industry’s growing commitment to sustainable energy solutions.